Latest News

- Electro Static Discharge Immunity Test

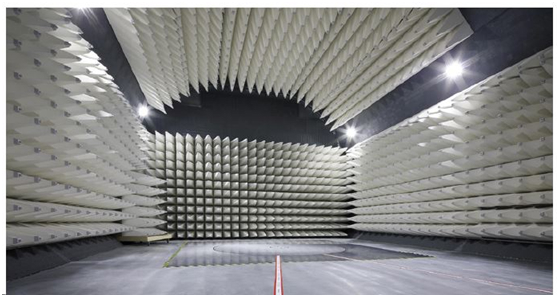

- Radiated Susceptibility/Immunity Test

- Electrical Fast Transient (EFT)/ Burst Immunity Test

- Surge Immunity Test

- Conducted RF Immunity Test

- Power Frequency Magnetic Field Immunity Test

- Voltage Dips, Short Interruption & Voltage Variations Immunity (AC & DC)

- Harmonic Current Emission Test

- Voltage Change, Fluctuation & Flicker Measurement Test

- Conducted and Radiated Emission Test

- Household Appliances, Air Conditioners & Refrigerators

- Switches & Control Gears, Power Electronics Equipment

- Telecommunication Equipment, Multimedia Equipment (Audio-Video & Information Technology Products), Electric Toys

- Electric Vehicle Components & Subassemblies, Automotive Electronic Components & Subassemblies, Rolling Stock Apparatus (Railways & Metro-rail Electronic Components & Subassemblies)

- Medical, Scientific & Industrial Equipment, Electrical Equipment for Laboratory (Test & Measuring Instruments)

- Electrical Lighting & Similar Equipment

- Aviation, Aeronautics & Maritime Electronic Components & Subassemblies, Equipment & Subsystems used by Dept. of Defence (Military Products & Components)

- Dry Heat Test/ High Temperature/ Burn- in Test

- Temperature Step Test

- Damp Heat Steady State Test/ Damp Heat (Cyclic) Test/ Moisture Resistance Test/ Tropical Exposure /Humid Heat, Cyclic Test/ Tropical Exposure Test

- Salt Mist Test/Salt Spray Test/ Salt Fog Test

- Change of Temperature/Temperature Cycling Test/Rapid Change Thermal Cycling Test/Thermal Shock Test

- Vibration Test (Sinusoidal & Random), Shock Test

- Ingress Protection Test (IP), Impact Protection Test (IK)

- Glow Wire Test, Needle Flame Test, Flammability Test (Test Flames – 50 W & 500W Horizontal and Vertical Flame Test), Hot Wire Ignition Test

- Proof and the Comparative Tracking Indices Test

- Free Fall Test, Vertical Drop Test/Drop Test

- High Voltage Test, Insulation Resistance Test, Supply Voltage Test

Hi Physix Laboratory” is committed to provide one stop solution to its esteemed customers by offering entiregamut of testing facilities.

To meet our Customers and Regulatory Bodies requirements and continuous improvement of ourorganization, we are continuously adding and upgrading our testing facilities.

Testing Facilities for Air Conditioners, Refrigerators & Freezers

“Hi Physix Laboratory” feels proud to announce that our laboratory has established a class apart testing setup for Testing of Air Conditioners, Refrigerators and Freezers.

As notified through Gazette Notification “Air Conditioner and its related Parts, Hermetic Compressor and Temperature Sensing Controls (Quality Control) Order, 2019” dated 05.12.2019, the testing of Air Conditioners, Hermetic Compressors etc. have been made mandatory in India as per the respective Indian Standards and will come into force with effect from 01.01.2022.

| Sl.No. | Products | Standards |

|---|---|---|

| 1 | Room Air Conditioners – Unitary Air Conditioners. | IS 1391 (Part 1):2017 |

| 2 | Room Air Conditioners – Split Air Conditioners. | IS 1391 (Part 2):2018 |

| 3 | Ducted and Package Air Conditioners. | IS 8148: 2018 |

| 4 | Deep Freezers (Hard Top Chest Freezers, Glass Top Chest Freezers (sliding, hinged and curved)) | IS 7872:2020 BEE Schedule – 25 |

| 5 | Room Air Conditioners (Windows Type & Split Air Conditioners). | As per SASO/ JIS/ ANSI/ISO/GB/AS/NZS/UAE.S /ASHRAE |

| 6 | Light Commercial Air Conditioners | As per BEE Schedule-24 |

| 7 | Split and Unitary AC | As per BEE Schedule-3 |

| 8 | Single Phase Split Air Conditioners | As per BEE Schedule-3(A) |

| 9 | Variable capacity Air Conditioners (Split and Unitary Air Conditioners) | As per BEE Schedule-19 |

| 10 | Refrigerators, Food-Freezers and Ice-Makers (Safety Requirements) | IS 302-2-24:1994 IEC 60335-2-24: 2010 |

| 11 | Refrigerators (Performance Requirements) | IS 17550 IEC 62552-1:2015, IEC 62552-2:2015, IEC 62552-3:2015 |

| 12 | Commercial Refrigerating Appliances (Safety & Performance Requirements) | IS 1474:1959 IEC 60335-2-89:2010 |

| 13 | Refrigerators with or Without Low Temperature Compartment | IS 1476 (Part1):2000 |